Revolutionary Bio-Adhesive: Strong, Enduring, and Recyclable Plastics from Cooking Oil

Imagine a world less reliant on petroleum-based plastics, a world where strong adhesives can be created from readily available, renewable resources. Recent research has brought that vision closer to reality with the development of a novel bio-adhesive derived from cooking oil - and the results are surprisingly powerful. This breakthrough offers a promising path toward more sustainable materials for a wide range of industries.

The Problem with Customary Plastics

For decades, we’ve depended on plastics derived from fossil fuels. These materials, while versatile, present significant environmental challenges. They contribute to pollution, are slow to degrade, and rely on a finite resource. You’re likely aware of the growing need for eco-amiable alternatives.

A Sticky Solution: Polyesters from Cooking Oil

Scientists have discovered that polyesters created from cooking oil exhibit exceptional adhesive properties. These polymers aren’t just strong; they’re also remarkably sticky, thanks to oxygen atoms within their structure. These atoms form robust bonds with various materials,a key difference from traditional hydrocarbon-based plastics like LDPE.

This unique characteristic allows for a level of adhesion previously unseen in bio-based materials.

Demonstrating the Strength: real-World Tests

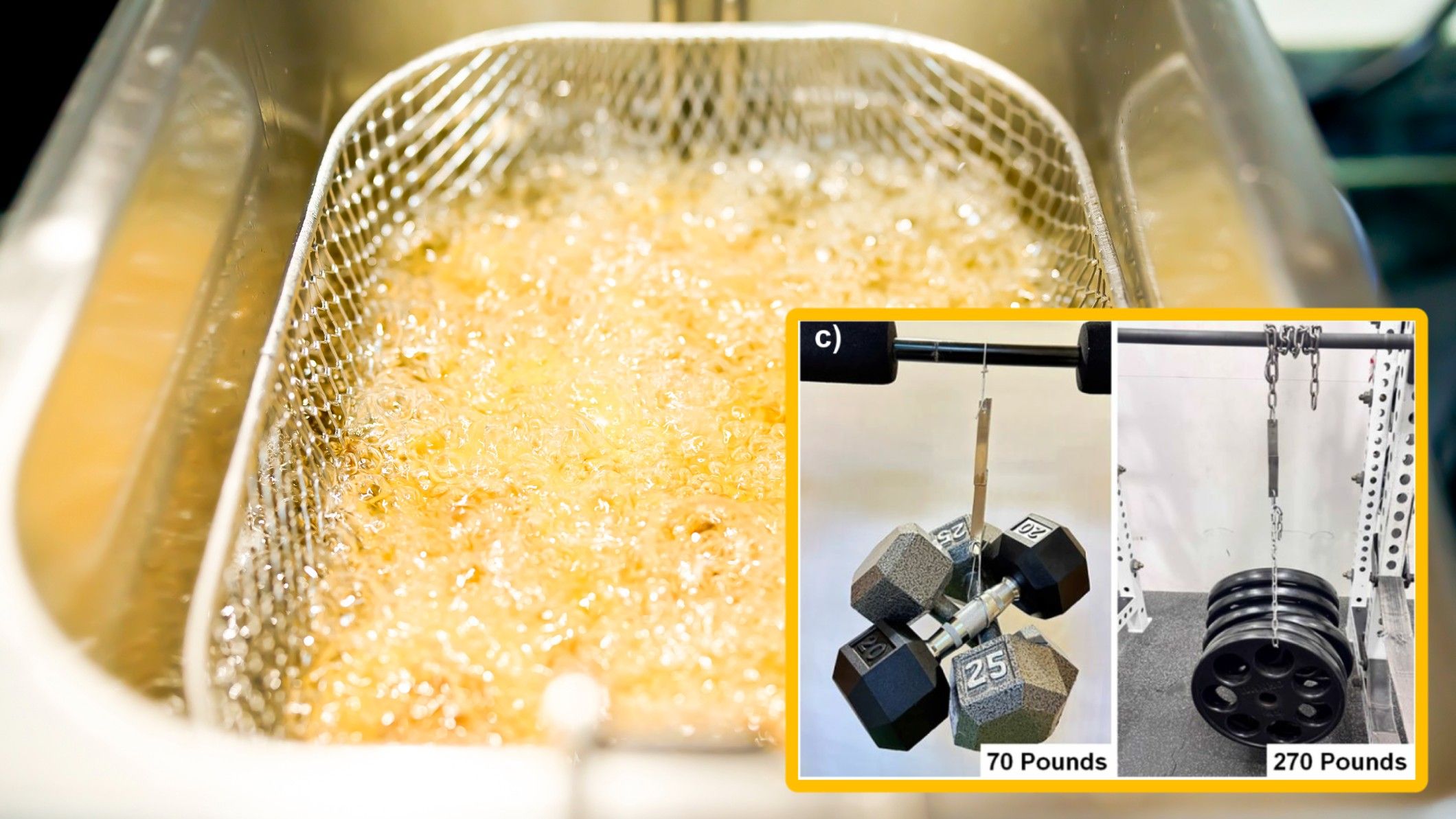

The adhesive strength of these new polyesters was rigorously tested, and the results are notable.

* Two stainless-steel plates bonded with the cooking oil adhesive held over 270 pounds (123 kilograms) without failing.

* Remarkably, the adhesive proved strong enough to tow a four-door sedan uphill.

* these performance levels rival, and in certain specific cases exceed, commercially available adhesives.

These tests clearly demonstrate the potential of this bio-adhesive for demanding applications.

Versatile Applications Across Industries

The unique properties of these polyesters open doors to a diverse range of applications. Consider these possibilities:

* Packaging: Creating stronger, more sustainable laminates for food and product packaging.

* Automotive: Developing eco-friendly adhesives for interior and exterior components.

* Medical Devices: Manufacturing biocompatible adhesives for medical applications.

* Electronics: Providing reliable bonding solutions for electronic components.

You can envision a future where many of the plastics you encounter daily are derived from renewable sources.

The Power of Recyclability

Beyond their strength and adhesive qualities, these polyesters boast another crucial advantage: recyclability. The researchers found that:

* The plastics could be easily broken down into their original components and remade into new plastic.

* Multiple recycling cycles showed minimal impact on the material’s properties.

* Some formulations could even be recycled alongside common plastics like high-density polyethylene and polypropylene.

This closed-loop system minimizes waste and maximizes resource utilization.

A Step Towards a Sustainable future

This research underscores the potential of utilizing nonedible biomass waste as a renewable feedstock. It offers a viable pathway to environmentally friendly alternatives to traditional, petroleum-based plastics. You can expect to see further development and refinement of this technology as researchers explore its full potential.

Ultimately, this breakthrough represents a significant step toward a more sustainable and circular economy, offering a promising future for materials science and environmental obligation.