MediaTek’s Automotive Chip Ambitions Hit a Roadblock: TSMC Arizona’s Certification status

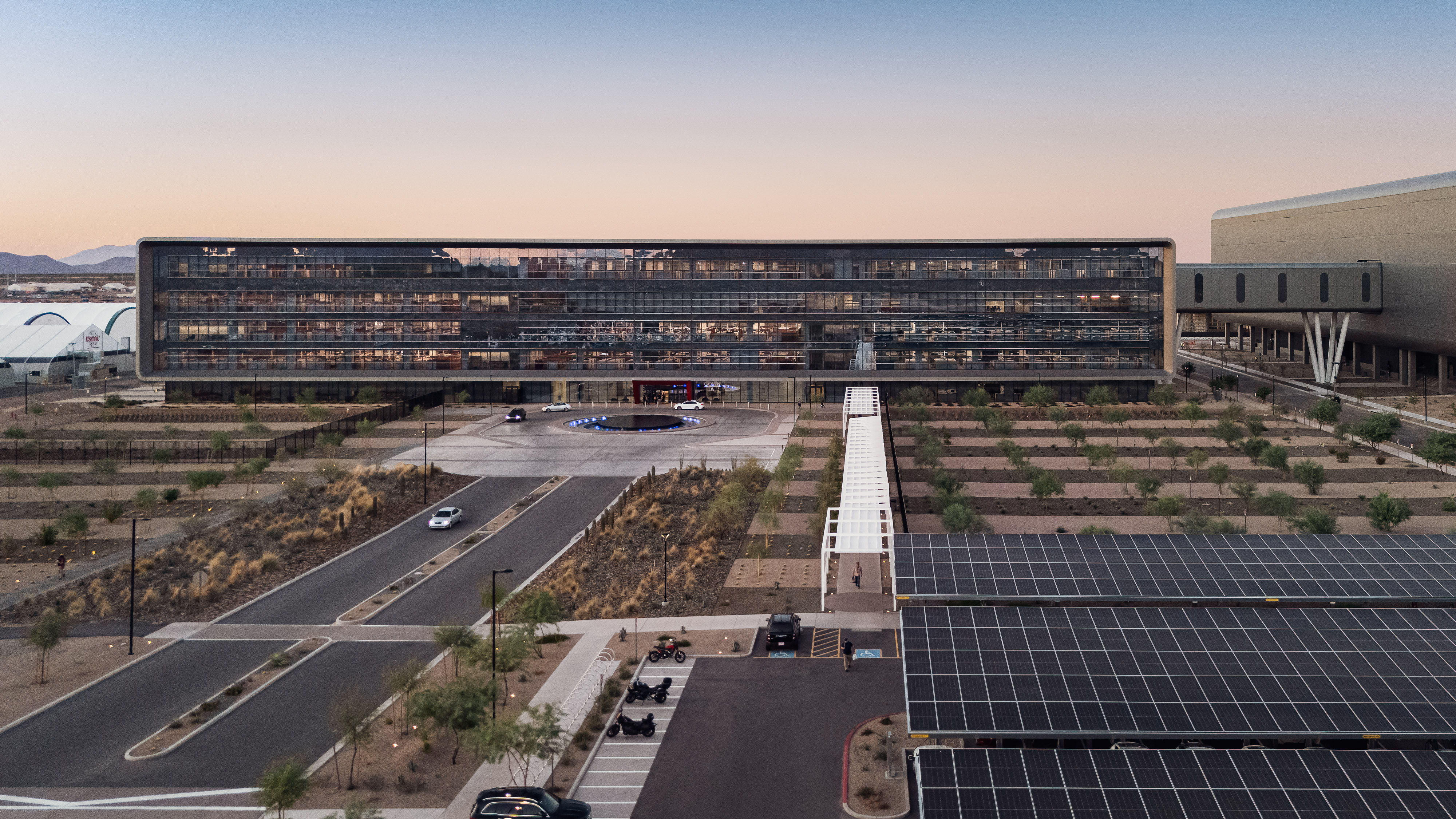

MediaTek, a leading fabless semiconductor company, is exploring expanding its automotive chip production. A key part of this plan involves potentially utilizing TSMC’s new Arizona facility (Fab 21). Though, a notable hurdle remains: whether the fab meets the stringent quality standards required for automotive-grade components. Let’s break down what this means for MediaTek, the industry, and ultimately, your next vehicle.

The Core Challenge: IATF 16949 Certification

The automotive industry doesn’t operate under the same tolerances as consumer electronics. Safety is paramount. Thus, automotive chips require adherence to the IATF 16949 standard - a globally recognized quality management system. This certification ensures consistent quality and reliability throughout the entire supply chain.

Currently, TSMC Arizona hasn’t publicly announced IATF 16949 certification. Initially, the fab focused on producing chips for consumer devices and high-performance computing using advanced processes like N5 and N4. This presents a problem. Without this certification, or a demonstrably equivalent automotive-qualified production process, it will be challenging for MediaTek to manufacture safety-critical automotive components at the Arizona facility.

Why Certification Matters - Beyond Just a Stamp of approval

It’s not simply about having a certificate. IATF 16949 compliance dictates a rigorous approach to manufacturing.This includes:

* Traceability: Knowing the origin and history of every component.

* Statistical Process Control (SPC): Monitoring and controlling manufacturing processes to minimize defects.

* Defect Detection: Implementing robust systems to identify and eliminate flaws.

* Reliability Testing: Ensuring components can withstand the harsh conditions found in vehicles.

MediaTek understands this.While the company itself doesn’t need to be IATF 16949 certified, it must ensure every partner in its supply chain – including TSMC – meets these requirements.

TSMC’s Automotive Processes – But Are They in Arizona?

TSMC does offer specialized process technologies (N5A, N4A, and N3A) designed for automotive applications. These processes often incorporate relaxed design rules to improve yield and reliability. However, the crucial question is whether TSMC Arizona has implemented these automotive-specific flows.

What This Means for Different Automotive Applications

The level of certification needed varies depending on the chip’s function within the vehicle:

* Non-Safety-Critical Systems: Infotainment and connectivity systems have lower requirements.MediaTek could potentially produce chips for these applications at Fab 21 even without full IATF 16949 compliance.

* Advanced Driver-Assistance Systems (ADAS), Powertrain, and Battery Management: These systems demand the highest levels of safety and reliability. They require adherence to standards like ISO 26262 and Automotive Safety Integrity Level (ASIL) certifications. For these critical components, MediaTek will likely need to continue relying on TSMC’s established automotive fabs in Taiwan - or wait for Arizona to achieve certification.

The Bottom Line: A Wait-and-See Approach

Unless TSMC Arizona adopts or replicates the automotive-grade manufacturing processes used in its Taiwan facilities, MediaTek’s ability to produce fully automotive-qualified silicon there will be limited.

This situation highlights the complexities of expanding automotive chip manufacturing capacity.It’s not just about building a fab; it’s about building a certified fab capable of meeting the industry’s demanding standards.

Stay Informed

Keep up with the latest developments in semiconductor technology and the automotive industry. Follow Tom’s Hardware on Google News or add us as a preferred source to receive our expert analysis directly in your feed.