#world #losing #fight #electronic #waste #hope

Report of the United Nations according to in a single year, we threw away 62 million tons of mobile phones and other electronic devices as waste. This number is expected to grow by roughly 33 percent by 2030. This is not only problematic due to raw material consumption, but also because e-waste can contain toxic and hazardous substances such as mercury and pose a threat to the environment and health. According to the United Nations, we are losing the fight against e-waste, as its volume is growing faster than efforts to recycle it.

The problem with electronic waste is not only that it is difficult to deal with it, but also that the production of such devices requires a lot of raw materials, the extraction of which is usually polluting and not done in compliance with human rights rules. China already dominates the processing of minerals vital to the green and electronic economy, and less than 10 years ago, the country began buying into extraction projects within the “lithium triangle” of Argentina, Bolivia and Chile – this area contains a significant part of the world’s lithium reserves. Lithium is mostly needed for device batteries, but similar problems also arise in the extraction of copper, gold and aluminum.

A 2018 research according to mining copper, gold and aluminum costs thirteen times more than recycling metals through e-waste. Such utilization involves disassembling and cleaning electronic devices, but this is generally not the case in developed countries, but in developing ones. are carried out, where informal recycling is typically unlicensed and unregulated. Here, people – often children – simply collect the valuable waste, disassemble the tools to extract the precious metals, then burn the rest and use various acids to extract the gold from it. This is usually done without any kind of protective equipment, which is extremely harmful to health and also heavily pollutes the environment.

They are trying to extract copper from electronic waste in Ghana – Photo: Miho Kibiki / Yomiuri

The manufacture of electronic devices is very water-intensive process: a smartphone requires 14,000 liters of water and a laptop requires 190,000 liters of water. Between 2007 and 2021, approximately 14.5 billion smartphones were produced, which equates to approximately 200 trillion liters of water, enough to fill almost 80 million Olympic-sized swimming pools.

Titanium is just one of the materials found in our digital devices; a small titanium mine in Chiapas, Mexico, about 250,000 liters of water uses up per hour, while a large mine produces 1-3 million liters in the same amount of time. Mines pollute the local Cacaluta River, fish die, animals get sick. The workers here develop hives, and cancer cases are rapidly increasing in the area.

One solution to the problem could be to produce less electronic waste, and one way to do this is to recycle used devices. By itself, using gadgets for a longer period of time can help a lot: if someone uses a smartphone for five years instead of two, they reduce their impact on water by more than half. The same goes for laptops. The problem, however, is that a device often becomes difficult to use even after two years, or even breaks down in that time.

This is where professional refurbishing comes into play: more and more companies deal with repairing used devices and reselling them. However, when we talk about refurbished electronic devices, most people still think of sufnituning, repaired laptops and phones tinkered at home, even though an entire industry is built – unfortunately very slowly – on refurbishing used but still usable smartphones, tablets and laptops.

A according to research otherwise, the younger generation is especially receptive to this: in 2023, almost half of digital consumers bought products they already owned. Of course, this includes used clothes and other household items, but the same applies to refurbished electronic devices.

no according to some sources a hidden trillion-dollar industry that’s only just starting to really take off. In the financial year 2022-2023, the European recommerce market increased to 94 billion euros, which represents a significant 12.3 percent share of the entire European e-commerce market. According to forecasts, this will expand to 14 percent in the next three years.

The renovation of these companies is based on strict rules, during the process the used electronic devices are restored to a new working condition. Through systematic post-collection inspection, repair, replacement of worn parts and deep cleaning of software/hardware, phones, tablets, laptops, PCs and their accessories get a new life and, perhaps just as importantly, a warranty that can increase customer confidence in the solution.

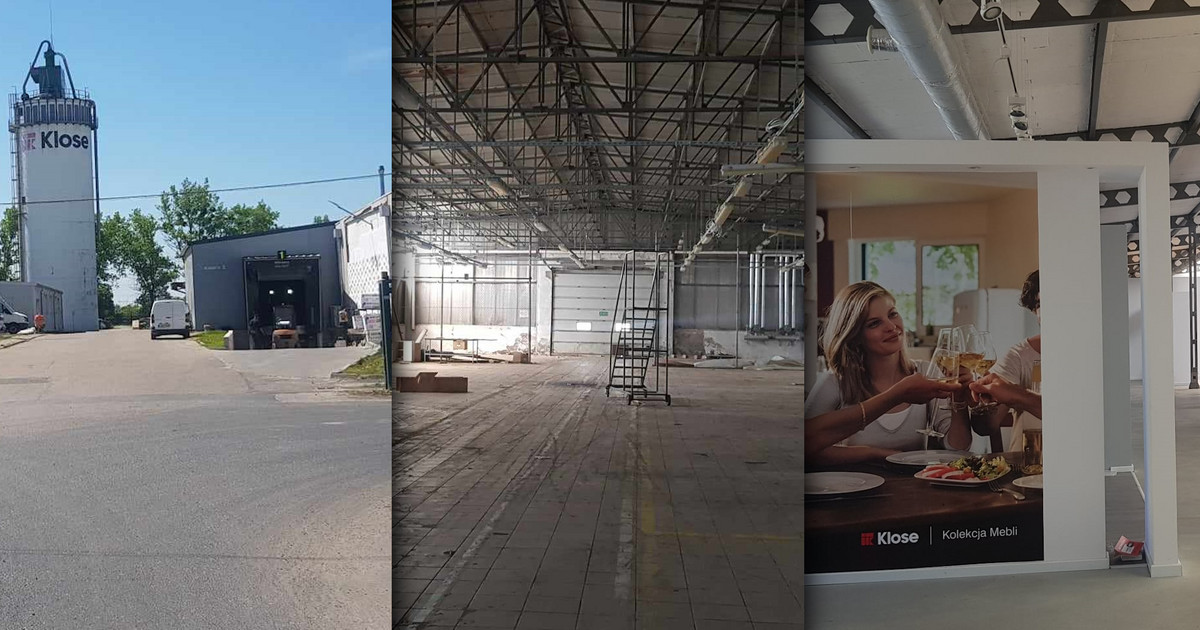

This is what the Hungarians in Slovakia deal with Furbify also, where they breathe new life into laptops and personal computers, but occasionally into robot vacuum cleaners and even electric scooters.

“Globally, only every thirteenth laptop is renewed,” said Furbify’s international business development manager, Tibor Forró, when Telex visited the company’s repair facility in Gúta. “To produce a laptop, 22 kilograms of chemicals and 190,000 liters of water are required.”

The company was founded in 2007, but the coronavirus epidemic gave it a real impetus, when e-learning and working from home came to the fore, and a child has developed. Now more than 150 people work for the company, which has renewed more than 250,000 devices in the last 17 years. They buy gadgets from all over the world and also give customers the opportunity to bring back their own bored gadgets for which they can get money or a coupon at Furbify. However, most of the incoming devices are not private: a significant part of the laptops to be refurbished are purchased from companies and institutes, which are found at brokerage events. These are typically less worn than personal laptops.

At Furbify, we had the opportunity to tour the factory and see how refurbished laptops are made. The first stop is always the dust removal unit, followed by manual cleaning, so that the small beauty defects that need to be repaired or that require the replacement of a component are clearly visible. After cleaning, there is a visual inspection, where the devices are classified into three categories: gold covers a completely flawless device, silver means a scratch or two, and bronze shows visible but minor damage.

Photo: Robert Nagy / Flying Arrow Stills

As for the repair, a two-man service team performs the immediate functional restoration: they install the screen, the keyboard, the battery. If the problem is greater than this, the device is sent to a larger service team, where more serious repairs are carried out. Furbify either repairs the device itself or replaces the defective parts with new ones, possibly used but in good condition. Administrators then hand the device over to the product manager, who prices it based on what price range it would otherwise be in and whether it has minor visual damage.

After the repair, of course, another test follows, and if necessary, another repair. The tools are put into the warehouse in such a way that they can be sold immediately. The entire process takes an average of 2 hours and 7 minutes, depending, of course, on how much the device needs to be repaired: the average cleaning time is 6 minutes, 12 tests take place in one hour, keyboard repair and battery replacement typically take 11 minutes. Configuration and carbon wrap takes 7 minutes each.

At Furbify, customers have the opportunity to assemble their own laptop: if you tell them what color laptop you want, how much memory and storage space you need, what language keyboard and what operating system you want the device with, the team will put it together accordingly. “The biggest challenge is that there is a difference between a used laptop and a used laptop,” said production manager István Veszprémi. It doesn’t matter if a computer that has been used for five years comes in from someone, or a barely used laptop comes from the Western European banking sector. However, the company offers a 2-year warranty for refurbished devices, regardless of condition.

The service team works on a laptop at Furbify – Photo: Nikoletta Nagy / Telex

Furbify does not work with phones, as the market in this area is more saturated. Telekom, for example, with re!commerce is working, so far it seems to be successful. “At the beginning of October last year, we launched recycled phones on the market, and our own customers choose them to a considerable extent – said Norbert Kreisz, Head of Device Management at Magyar Telekom. – Customers expect the price difference, but also the quality. Such phones can be a real alternative for young people, where affordability is important.”

Refurbished phones can be purchased online at Telekom for the time being, 45 percent of them are now sold through a personal channel, i.e. through a call center. “We don’t want to have stagnant inventory. This is more specialized than new sales, because we can work from what appears as an offer to the partner,” said Norbert Kreisz.

And the partner is a re!commerce, where they are currently innovating 22 device types and trying to keep all activities within Europe to improve sustainability. However, new parts still come from China, and when replacements are needed, they are used.

“Roughly 1 percent of the devices are unusable, we extract the raw materials from them,” said János Zilai, sales manager of re!commerce. “29 percent of the incoming devices are not worth renewing, in which case we select the parts that can still be used. Roughly half of the remaining 70 percent is simple renovation, the rest needs to be repaired.”

According to the data of re!commerce, 5.5 percent of mobile phones in use are refurbished and 10 percent are used in the European Union, in Hungary these numbers are around 3 and 14 percent. If the phone does not need to be repaired, the renovation will take place in 1-2 days.

Norbert Kreisz said that new phones are increasingly environmentally conscious, but also more complex, which makes recycling difficult. Currently, 2-3 percent of the phones sold at Telekom are refurbished, but for now there is no financial incentive for users to bring in used phones that are dusty at home – unlike Furbify, Telekom does not pay customers for returned devices.

:quality(85)/cloudfront-us-east-1.images.arcpublishing.com/infobae/OIK4XEJI4JE2HGL4HCMMIZWHGI.jpg)